Quality Policy

The Quality Control supervises compliance with the company’s Quality Policy on all work stands, with a particular emphasis on production and customer satisfaction with our products. Product quality control at every stage of production helps to minimise the quantity of goods which are inconsistent with technological documentation, whereas the final control eliminates any rarely occurring defects.

Cooperation with our customers allows for immediate response to any remarks they might have in addition to any new requirements regarding our products.

Application of state-of-the-art treatment technology as well as constant and reliable control at every stage of production prove our reliability and high quality of final products offered by KANEX. All system elements are subject to 100% quality control.

The entire production control process, commenced with control of materials used in production by examining compliance of individual batches with technical parameters, is completed with preparation of a test report, the so-called “Final Acceptance Report”. That document constitutes a basis for releasing a product to the recipient.

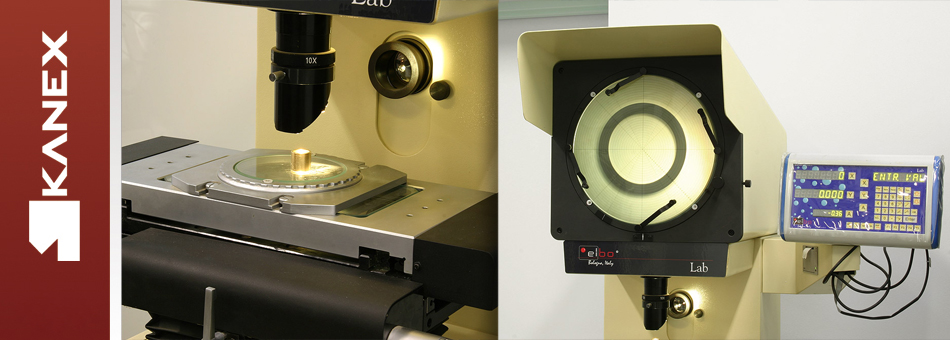

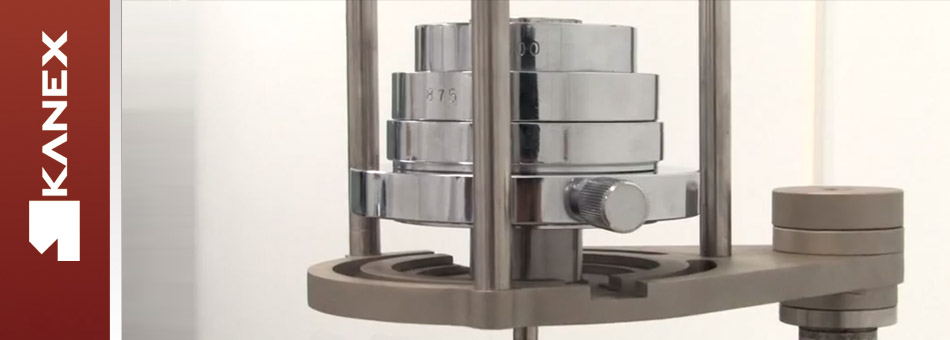

The Quality Control, which is in charge of the entire production process, is equipped with state-of-the-art testing and measuring instruments which allow for conducting thorough checks of manufactured goods. All the required tests and measurements, are performed in accordance with applicable regulations of the European Union.

We are aware of the fact that complete elimination of a human error in the manufacturing process in impossible. We can, however, minimize its occurrence by introducing the FMEA system which we have recently begun implementing. Such a method aims to prevent effects caused by defects which may occur in the designing and production stages.

KANEX confirms, that is able at customer’s request to produce the components according to:

- the RoHS Directive on restrictions on the use of hazardous substances in products.

- the REACH Directive which aims at improvement of human health and environmental protection from the risks that can be posed by chemicals.

Furthermore, positive ratings given by our customers prove the high quality of our products. We usually receive the so-called PPM rate ( Parts Per Million), which indicates the number of defects per million. The lower the value of the index, the more defect-free the process is. We always stand on the highest podium in our clients’ classification - receiving “zero” ratings (PPM=0). As an “A-class” supplier, we deliver high quality products which fulfil our customers’ expectations.

Over many years we have become known as a trustworthy and flexible partner in terms of deliveries, timing and reliability of supplies, but most importantly, the quality of our products. We are aware of the fact that customer’s satisfaction contributes to development of our company and strengthen its market position.